Company

Efficiency, thermal management, glare reduction, lenses and reflectors, material selection, lighting quality and connectivity are just some of the constantly evolving topics studied and tested in our Research & Development department.

Innovative laboratories

Our UL certified laboratories are one of our distinctive assets. We test materials, light sources and entire products.

Our dedicated and passionate team of technicians and engineers, virtually simulate and exacerbate the environments where products will be placed, measuring effects and behaviours.

It is the trial by fire of each component, where monsoon rain, salt fog, mechanical shocks, electrical stress and other stressful conditions, reproduce in a few hours the effects of decades of operation of the structures and equipment. Tests are carried out on luminaires, light sources, materials and finishes.

It’s a safety test on the luminaires’ housing. This test determines the degree of resistance to water ingress and takes place in a controlled temperature environment, according to EN60598-2-3 and EN60598-1 standards.

It’s a performance test designed to test protective coatings. The test is characterised by exposure to fluorescent UV lamps and water. The ‘decorative’ features are examined before and after the cyclic accelerated aging by means of UV-A or UV-B radiation and condensation in accordance with ISO 11507. The comparison takes place both through a preliminary visual inspection and by instrumental testing to identify differences in colour (ISO 7724) and index of brightness. The test equipment is located in an appropriate environment which requires specific systems such as, for instance, water purification.

It’s a safety test on the luminaires’ housing. The test determines the degree of resistance to external mechanical impact and takes place in a controlled temperature environment. The reference standard is the EN62262.

It’s a safety test on light fixtures, to determine their resistance to cyclic heating and cooling under operating conditions. The test takes place in a controlled temperature environment at 35° C. Its purpose is to check that the light fixture characteristics do not change over time. The reference standard is the EN60598-2-3 and EN60598-1.

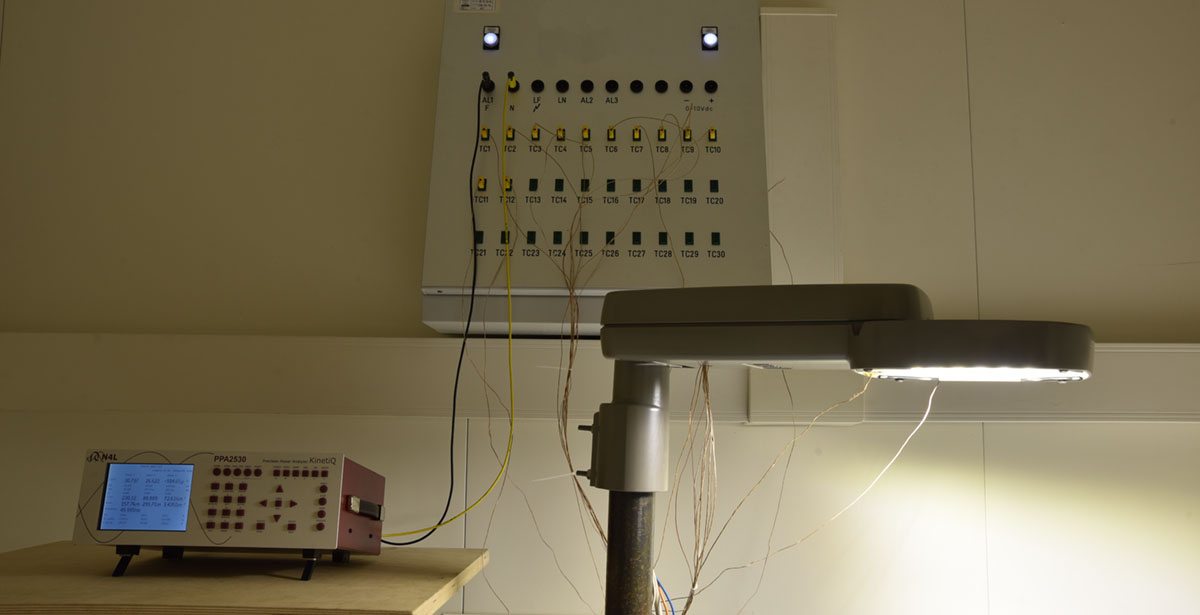

It’s a safety test on light fixtures. It tests light fixtures when critical temperatures for safety are reached during normal or abnormal operation. Light fixtures are tested to verify their thermal, mechanical and electrical safety as specified in the harmonised product standards under Directive LVD, EN 60598-2-3 and EN 60598-1. This test also includes safety tests on LED modules, according to product standard EN 62031. LED modules are usually tested as built-in components of the lighting unit. This type of tests is carried out in a constant temperature environment.

It’s a performance test on light fixtures and light sources. A mirror goniophotometer is used to determine performance, light output (LOR [%]), efficacy (η [lm / W]) and luminous intensity distribution in accordance with EN 13032-1 and UNI 11365. The room where the test equipment is located is air conditioned with constant temperature, humidity and air speed.

It’s a performance test on light fixtures and light sources. This is where the performance of lamps and LED modules (decay of the luminous flux, efficacy and colour characteristics) is tested. The room housing the spectroradiometer, where the colorimetric characteristics of light sources can be identified, is air conditioned, but without temperature control.

This is a performance test designed to test protective coatings. Paints and other types of protective coatings are tested to determine their resistance to corrosion by neutral salt spray aging according to ISO 9227 standard.

It's a performance test on light fixtures and light sources: decay of the luminous flux, efficacy and colour characteristics. The room is air conditioned, but without temperature control. In particular, this test is done to assess and measure lamps aging. For this test the reference standard is the EN 13032-1.

Light room

It’s our most impressive and technologically advanced test setting, a sort of wind tunnel, where light blows instead of wind.

Our Light Room is the place where clients and designers can measure the reach of every new idea, up to the degree of comfort that can be felt by a motorist or a pedestrian walking along a hypothetical waterfront.

All this is done through a realistic and immersive simulated experience created by a simulator specifically built.

A valuable component for all projects, often required by universities and technical institutes in order to perform tests and very specific simulations, otherwise impossible to conduct anywhere else in Europe.

Lighting Schemes Simulation

A setting similar to a street makes it possible to simulate a real installation, with the same characteristics in terms of distance between posts and street geometry proportions. These characteristics make it possible to assess lighting effects at ground level, also thanks to a porous covering such as asphalt. During this test, it is possible to walk around and see the results with your own eyes. The maxi screen also shows the equivalence between calculations (spot and isolux) and the actual situation.

Visual comfort test

The installation of light fittings on a post, with a set distance between each one, means it is possible to assess the visual comfort of our lighting systems and even to compare them with competitors’ systems. This information, which is barely identifiable using standard simulations or technical lighting calculations, is never totally appreciable without real experience. In fact, the eye is the ultimate and only instrument available when it comes to assessing the real comfort of a light source.

Lighting Quality test

Lighting quality can be wholly measured in a laboratory. The most faithful perception of lighting colour is certainly seeing it as it really is. LEDs in particular are light sources with great differences in colour according to the way in which the emission angle varies. Therefore, it can be surprising how LED sources can be seen in different colour tones on the ground: some areas are lighter blue or greener than others. This visual test allows us to assess and select the ideal sources and optical systems that best correspond to lighting of the highest quality.

Product development

The genesis of a product is not a linear process but a shared activity, with different facets, sometimes it starts with

testing a new technology sometimes from the intuition of a designer.

Innovation takes slowly shape and the idea gets prototyped, tested, engineered and finally industrialized to meet commercial targets.

The Foundazione’s knowledge, Laboratory tests, simulations in the Light Room, experiments on materials and technological partnerships are the mix of competences and actions that take a product to the market.